Student Experience

Algonquin College is proud to provide a diverse and dynamic student experience. Check out the highlights below to get a sense of what to expect as a student in the program.

Please Note: this program consists of 4 semesters delivered consecutively with no break.

Success Stories & Testimonials

Check out Christopher’s experience.

Yakin shares his experience in the Manufacturing Engineering Technician program.

Employer Testimonials

“Over the last 16 years, Billet Precision Corporation has hired dozens of Algonquin Graduates now in key positions paying well over $65k. Each year we hire from the graduating classes and find it very beneficial to sustain our company growth”

Joe Shuster

President of Billet Precision Corporation

“The National Research Council Apprenticeship Program was developed to attract, train, and retain highly skilled Individuals who will carry on NRC-DFS’ tradition of technical excellence, in conventional as well as new technologies. Algonquin College has been a key source for top-quality employees coming into the National Research Council with a solid foundation of technical training – ready to tackle our Apprenticeship Program head-on!”

Allan Horner

Supervisor

National Research Council Canada

In this program, students have many chances to be involved in different projects including but not limited to CNC conversational programming, 3D scanning, Quality Control with CMM (Coordinate Measurement Machine) and Optical Comparator Machines, manufacturing of assemblies such as a gearbox (A-Z processes needed including CNC programming, machining to final inspection reports) and many other hands-on course projects supporting advanced manufacturing skills.

Students complete machining procedures/tool paths on CNC simulators without any CNC programming software and apply what they learned about conversational programming.

In the 3D printing and Additive Manufacturing course, the students have a chance to learn about Generative Design based on AI (Artificial Intelligence) and explore new ways of manufacturing parts on cloud-based software. They can 3D print or CNC machine final generated parts produced and explored by AI on defined design conditions. They have options to do 3D scanning and/or do inspections on the final products manufactured by 3D printing or CNC machining.

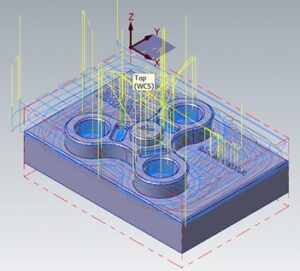

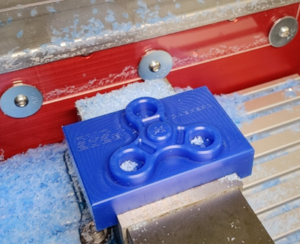

Students do supervised activities on CNC machines parallel to their CNC classes to be more comfortable with using MDI commands and do proper setup while they can design their own 3D model, verify the CNC programming, and finalize it on CNC machines to manufacture their own designed parts.

Project completion certificates including Mastercam/Fusion 360 CNC programming, CNC machining, 3D scanning, 3D printing, and inspection techniques are available for those students who would like to do more and experiment with what they learned in some courses on top of the actual class time.

On a visit to Central Wire Industries in Perth, Ontario, students from the Manufacturing Engineering Technician program handed over several finished, custom designed and manufactured Wire Tensioner devices.