Project Summary:

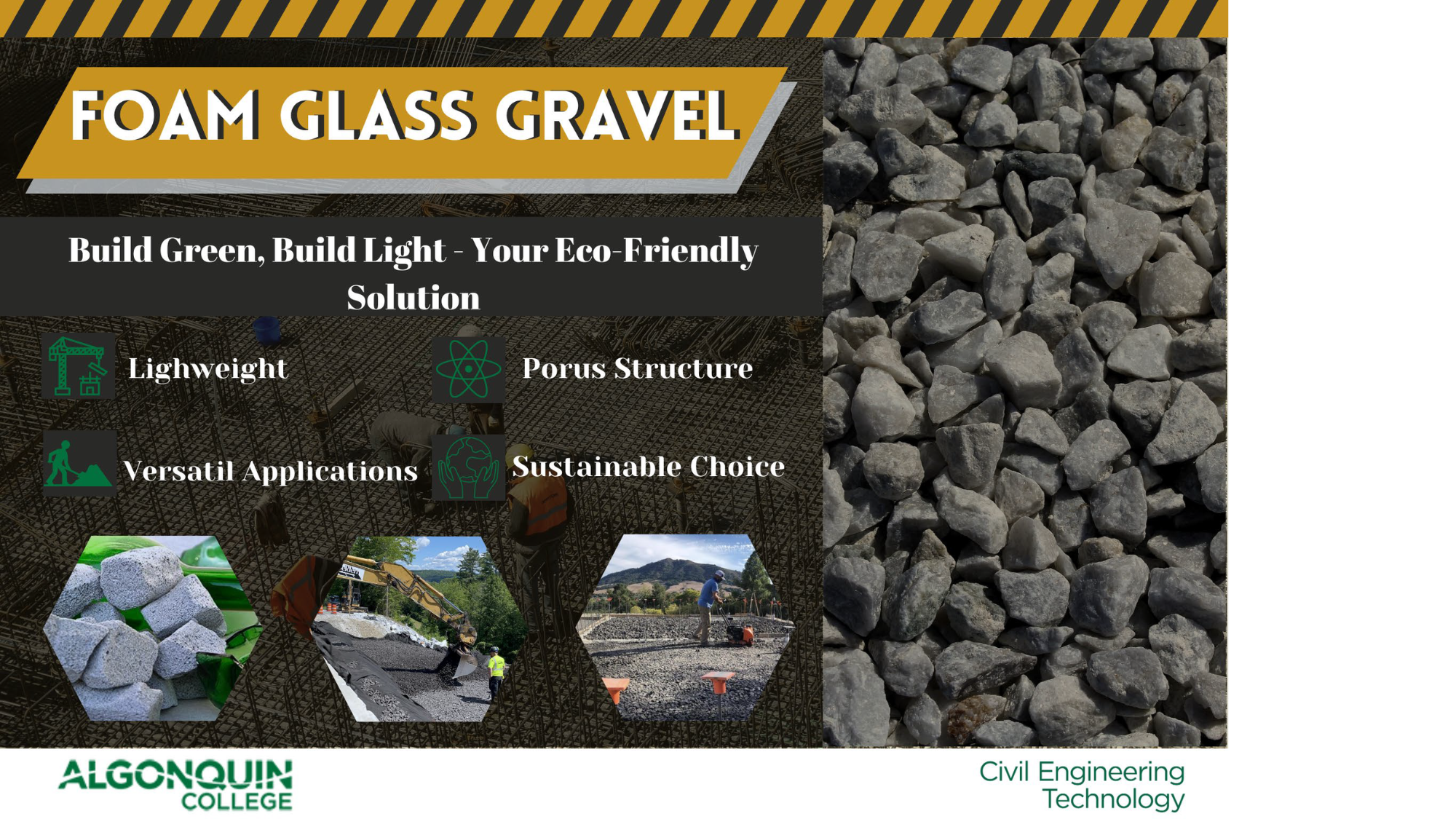

Foam Glass Gravel (FGG) was evaluated based on the American Society for Testing and Materials (ASTM) standards to determine its potential as a lightweight fill material for infrastructure and construction projects.

| Client | Blaine Kenedy | |

| Professor(s) | Francesco TangoraLaura McHugh | |

| Program | Civil Engineering Technology | |

| Student Team Members | Celine Kavanaugh, Johan Steven Pinto, Abdul Rahman Doidary, Mohamed Ndoye |

Project Description:

The inspiration to explore the potential of Foam Glass Gravel as a backfill material for the team’s project arose from Blaine Kennedy’s research conducted at Geo Glass Ottawa. Recognizing FGG’s success in Europe, Blaine initiated research but faced obstacles due to the increased costs associated with ASTM standards testing. However, Blaine’s provision of an FGG sample enabled the team to conduct tests in the laboratory facilities at Algonquin College.

The team explored FGG, also known as cellular glass aggregate, as a potential solution to the limitations of EPS blocks and aggregates. FGG is crafted from recycled glass, a foaming agent (such as carbon), and a fluxing agent (like limestone). This mixture undergoes heating upwards of 900 degrees Celsius, causing the foaming agent to decompose and release gas bubbles, creating a cellular structure within the glass. The resulting Foam Glass is then crushed into gravel-sized particles.

Research findings suggest promising attributes of FGG, including notable impact-absorbing capabilities and insulative properties. Its lightweight nature also renders it suitable for various applications, such as airport EMAS (Engineered Materials Arresting System), below-grade building insulation, and landscaping projects.